Manston Production Centre

Manufacturing

The current specialised processes carried out in Manston:

- Cable Assembly

- Aluminium Brazing

- Pipe Bending

- Tube End Forming

With specialist machinery Manston Production Centre are able to produce and ship products out to purchasing customers.

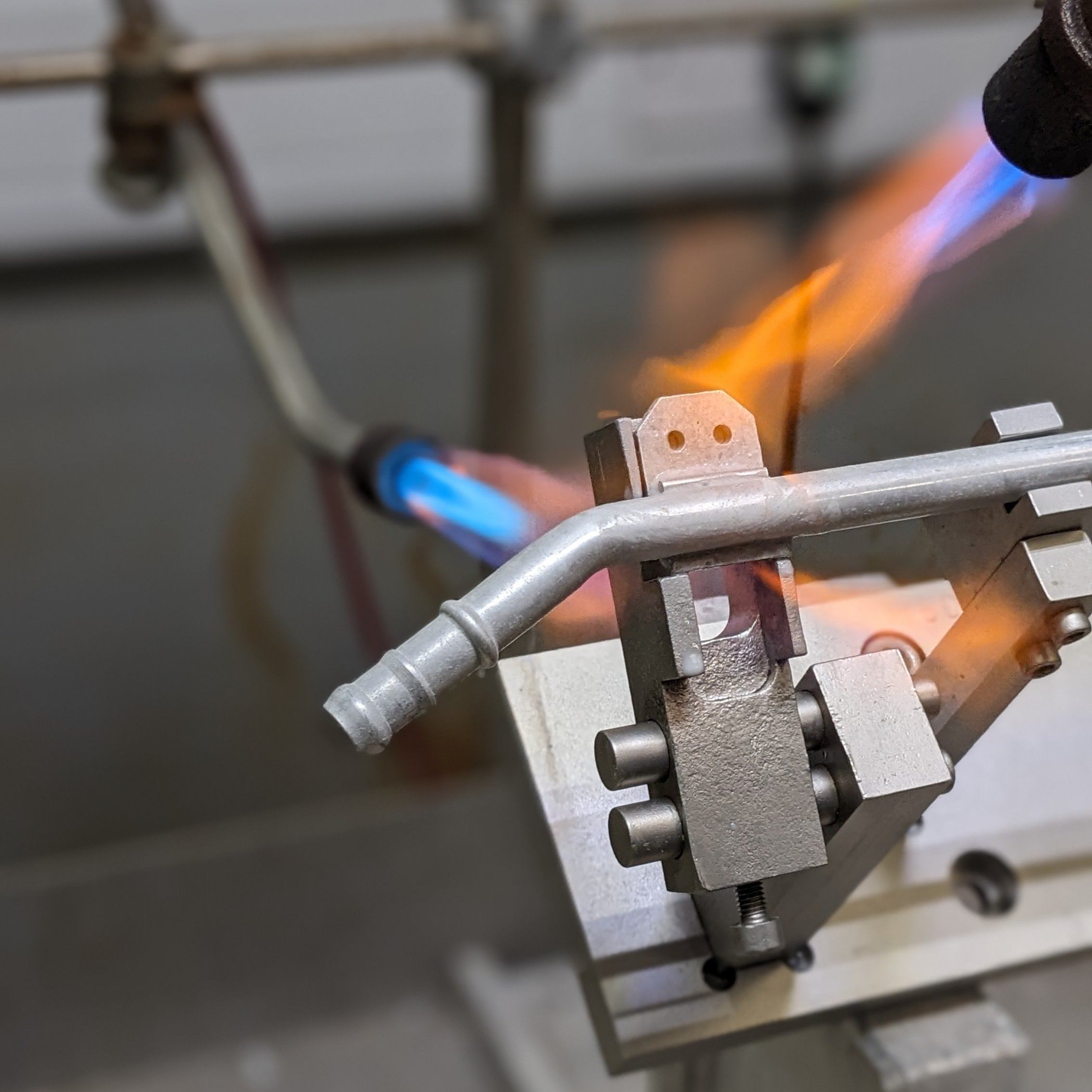

Aluminium Brazing

Aluminium brazing is the process of joining two sections of aluminium together with the use of a filler metal, that has a lower melting point than the aluminium parts. Since the filler metal will melt before the aluminium, the molten filler metal will cover the join of the parts, and once cooled, permanently bond the aluminium pieces together.

Aluminium brazing takes place in temperatures of 600°C, where our systems are controlled by PLC processors with full automation capabilities. This system ensures that the time of the torches is controlled and kept constant to ensure uniformity across parts.

Currently at Manston there are a variety of different brazing machines, this includes, six-station rotary brazing ovens, sliding brazing ovens and manual brazing stations. This machinery provides Cohline UK with the ability to braze large quantities of aluminium pipes and fittings in house.

Due to the complex design of some pipes and fittings, some of our machines will braze all parts together at once on custom made jigs.

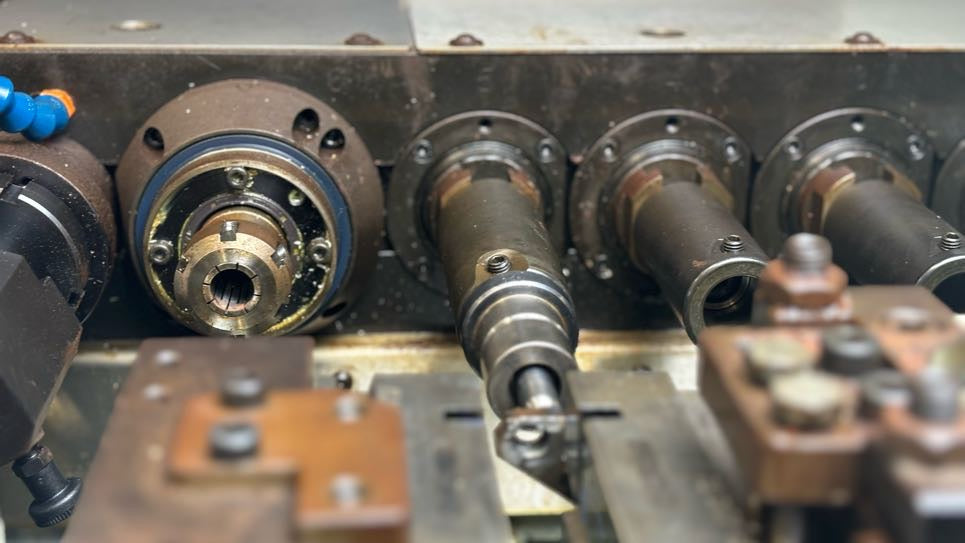

Tube Bending

Part of our core competence is the bending of tubes. COHLINE has the optimum process in-house for every application. In total, more than 100 bending machines are in operation in the COHLINE Group.

Tube bending historically has been one of Cohline UK’s main manufacturing capabilities, creating bespoke parts such as fuel lines, engine cooler lines, and more. Manston production centre has both CNC and manual bending machines to cater to different products, with the ability to bend to the tightest tolerances.

The hydraulic CNC machines are a mixture of Left-hand and Right-hand bending machines, with some of the machines having automation capabilities. The apparatus cater to various different metals types and compositions.

Not only does Cohline use bending machines but we also have the ability to hand bend tubes for prototypes and small batch production.

Tube End Forming

Another one of our core competencies is tube end forming. We have had years of experience and knowledge on the process of cold forming tube parts. Moulding fitting connections directly to the tubes is a cheaper and more efficient process then that of soldering fittings together, whilst still providing the same level of quality of the finished product.

We have the capabilities to mould a wide range of geometries and materials with our processes, whether that be simple standard hoses, high-pressure sealing heads, special hoses for extreme requirements and everything in between.

We have the capabilities to mould a wide range of geometries and materials with our processes, whether that be simple standard hoses, high-pressure sealing heads, special hoses for extreme requirements and everything in between.

Quality Testing

Our Quality standards are based on: the satisfaction and expectations of our customers, products effectiveness, as well as technical and economical conditions. Quality awareness is reinforced and accomplished by continual information, motivation, and training for employees.

Test Procedures are in accordance with valid procedural instructions and take the latest development in technology into account to ensure uniformity.

- Follow a zero-fault strategy (preventing faults rather than focusing on detecting them)

- Develop products that offer our customers competitive advantages

- Finished Product Inspection: Each product undergoes a thorough multi-point inspection before approval, including visual inspection, dimensional verification, and functional testing.

- Develop the quality competence of our supplies.

- Plan solid and competent manufacturing procedures

- Integrate all employees with responsibility for the quality of our products and services.

When you purchase our products, you're not just buying an item—you're investing in peace of mind. Our comprehensive quality assurance process ensures that every product bearing our name is worthy of your trust and confidence.